Powered by CertiPLUS

Certified Lean Six Sigma Black Belt (CLSSBB) certification enhances leadership and problem-solving skills, enabling professionals to manage large projects and optimize processes.

The Certified Lean Six Sigma Black Belt (CLSSBB) certification enhances advanced process improvement skills. It prepares professionals to take on leadership roles in managing complex projects.

With this certification, individuals are equipped to drive organizational efficiency through the use of Lean Six Sigma methodologies.

Certified Black Belts play a key role in optimizing processes and implementing data-driven solutions to improve performance.

- Your first stepping stone to a career in the field

Exam Pattern

Multiple Choice Questions

Mode of Exam

Online from Home or Office

Duration of Exam

3 Hours

Open Book/Closed Book

Closed Book Exam

Certification Validity

3 Years

About Program

The Certified Lean Six Sigma Black Belt (CLSSBB) program trains professionals to lead large-scale process improvement projects using advanced Lean Six Sigma methods. It focuses on process optimization, statistical analysis, and leadership skills.

Graduates are equipped to drive continuous improvement, mentor other belts, and take on senior leadership roles in organizations.

1. Overview of CLSSBB

The Certified Lean Six Sigma Black Belt (CLSSBB) certification is a prestigious credential designed for professionals who lead complex process improvement projects. It validates expertise in applying Lean Six Sigma principles and methodologies to eliminate waste, improve processes, and deliver measurable results. CLSSBB professionals typically oversee larger, high-impact projects and guide Green Belts and teams in organizations across industries like manufacturing, healthcare, finance, and IT.

2. CLSSBB Certification Requirements

- Educational Requirements:

- With a Four-Year Degree (Bachelor’s or Equivalent): 5 years of professional experience in process improvement, with a focus on applying Lean Six Sigma methodologies.

- With a High School Diploma or Associate’s Degree: 8 years of professional experience in process improvement or related fields.

- Project Management Experience: Must have a significant track record of leading projects using Lean Six Sigma tools, with experience in all stages of process improvement from defining the problem to ensuring sustainability.

- Training Hours: A minimum of 40 hours of formal Lean Six Sigma Black Belt training from accredited programs or institutions is required.

- Project Completion: Candidates must typically provide documentation of at least two projects where Lean Six Sigma methodologies were applied to achieve significant process improvements.

3. CLSSBB Exam Overview

The CLSSBB exam assesses candidates’ deep understanding of Lean Six Sigma concepts, tools, and techniques. As of the latest update, the exam consists of:

- 150 multiple-choice questions

- Time limit: 4 hours

- The exam evaluates the ability to use advanced tools, data analysis techniques, and strategic problem-solving methodologies in complex environments.

4. Key Areas Tested in the CLSSBB Exam

The CLSSBB exam covers a broad range of topics, with emphasis on the following areas:

- Define Phase: Identifying critical project goals, creating project charters, defining customer requirements, and identifying stakeholders.

- Measure Phase: Advanced measurement techniques, data collection methods, and statistical tools for baseline measurements.

- Analyze Phase: Using statistical tools to identify root causes, process analysis techniques, and advanced data analysis methods like hypothesis testing and regression analysis.

- Improve Phase: Developing solutions, applying Lean tools (such as Kaizen, 5S, and value stream mapping), and optimizing processes.

- Control Phase: Ensuring sustainability of improvements using control charts, statistical process control (SPC), and implementing systems for long-term process monitoring.

5. Lean Six Sigma Tools Covered

CLSSBB candidates are expected to demonstrate expertise in a variety of Lean Six Sigma tools, including:

- Advanced Statistical Tools: Regression analysis, hypothesis testing, ANOVA (Analysis of Variance).

- Control Charts & Process Control: Monitoring process behavior to ensure stability and sustainability.

- Root Cause Analysis Tools: Fishbone diagrams, Pareto charts, and Failure Mode and Effects Analysis (FMEA).

- Design of Experiments (DOE): Planning experiments and analyzing outcomes to optimize processes.

- Value Stream Mapping & Kaizen: Identifying and eliminating non-value-added activities to optimize the flow of processes.

6. CLSSBB Exam Process

- Step 1: Meet Eligibility Requirements: Ensure you meet the experience and training requirements.

- Step 2: Apply for the CLSSBB Exam: Complete your application on a Lean Six Sigma certifying body’s website. After approval, you can move on to schedule your exam.

- Step 3: Pay the Exam Fee: Pay the exam fee, typically between $400 and $600 depending on the certifying body.

- Step 4: Schedule the Exam: Once your payment is processed, schedule your exam through an authorized exam provider like Pearson VUE. The exam can be taken at a testing center or online (proctored).

- Step 5: Prepare for the Exam: Study using Lean Six Sigma Black Belt study guides, sample tests, and review materials.

- Step 6: Take the Exam: The exam consists of 150 questions, and you’ll have 4 hours to complete it. Results are typically available immediately after the exam.

7. CLSSBB Exam Costs

- Exam Fees: The cost for the CLSSBB exam typically ranges from $400 to $600, depending on the certifying body.

- Study Materials: Additional expenses for study materials, guides, or courses may range from $200 to $500.

8. Benefits of CLSSBB Certification

- Career Advancement: CLSSBB certification is highly regarded and opens up significant career opportunities in process improvement, project management, and operational leadership.

- Increased Earning Potential: Black Belt professionals often command higher salaries and are sought after for leadership roles in process improvement projects.

- Skill Development: The certification equips professionals with advanced problem-solving, data analysis, and project management skills that can be applied to large-scale projects.

- Organizational Impact: As a Black Belt, you will lead major process improvement initiatives, driving efficiency, reducing waste, and enhancing organizational profitability.

9. CLSSBB vs Other Certifications

- Black Belt vs Green Belt: While Green Belts manage smaller projects and assist with data collection and analysis, Black Belts lead larger, more complex projects and have a strategic, leadership role within organizations.

- Black Belt vs Yellow Belt: Yellow Belts are entry-level roles in Lean Six Sigma, generally supporting teams. Black Belts are expert leaders who manage project teams, mentor Green Belts, and drive organizational improvements.

- Black Belt vs PMP (Project Management Professional): The PMP focuses on general project management principles, while CLSSBB emphasizes process improvement using Lean Six Sigma tools and techniques.

10. Continuing Certification Requirements (CCR)

- Recertification: Some Lean Six Sigma certifying bodies require recertification every 3 to 5 years to ensure that Black Belts maintain their skills and knowledge.

- Professional Development: Ongoing education and participation in Lean Six Sigma projects and training sessions are encouraged to keep up with emerging trends and methodologies.

11. Exam Preparation Tips for CLSSBB

- Master the DMAIC Methodology: Understand each phase in-depth, as it forms the core of the certification. Focus on advanced tools like hypothesis testing and design of experiments.

- Practice with Sample Questions: Familiarize yourself with the exam structure and content by practicing with sample questions. This will improve both your test-taking skills and time management.

- Study Statistical Tools: Make sure you are comfortable with advanced statistical concepts such as regression analysis, control charts, and hypothesis testing, as they are heavily emphasized in the exam.

- Participate in Study Groups: Join online forums or local study groups where you can share knowledge and resources with other candidates.

Conclusion

The Certified Lean Six Sigma Black Belt (CLSSBB) certification is a highly valuable credential for professionals seeking to demonstrate advanced expertise in process improvement and lead large-scale projects. With its emphasis on data-driven decision-making and continuous improvement, CLSSBB offers professionals the tools to make significant organizational impacts, increase efficiency, and drive cost reductions. Earning the CLSSBB certification will position you as a leader in the field of process improvement and open doors to greater career opportunities and higher earning potential.

Key Highlights

- 620 Hrs of Applied Learning

- 218 Hrs of Self-Paced Learning

- 50+ Industry Projects & Case Studies

- 24*7 Support

- 1:1 Mock Interview

- iHUB DivyaSampark, IIT Roorkee Certification

- 2 Days Campus Immersion at IIT Roorkee

- Top 2 performers per batch will receive Rs 80000 in fellowship*

- Free Voucher for Exam AZ-900: Microsoft Azure Fundamentals worth $99

- 90+ Live Sessions Across 11 months

- Learn from IIT Faculty & Industry Practitioners

- One-on-One with Industry Mentors

- Dedicated Learning Management Team

- No-Cost EMI Option

- Designed for Working Professionals and Freshers

- Up to Rs. 50 Lakhs startup Incubation Support*

- 3 Guaranteed Job Interviews upon movement to Placement Pool

Career Transition

- 55% Average Salary Hike

- 55% Average Salary Hike

- 12000+ Career Transitions

- 400+ Hiring Partners

Who Can Apply for the Course?

- Individuals with a bachelor’s degree and a strong interest in learning AI and data science

- IT professionals looking to make a career transition as data scientists and artificial intelligence engineers

- Software Developer, Project managers, Non-Technical Professionals & Entry-level professionals looking to build their careers in artificial intelligence and data science

- Undergraduate freshers with an interest in Data Science & AI

What roles can a person trained in data science and artificial intelligence play?

Senior Data Scientist

Understanding problems and building models based on the data collected and leading a team of data scientists.

AI Expert

Developing strategies for frameworks and technologies to develop AI solutions and drive business success.

Machine Learning Expert

Using various machine learning tools and technologies, building statistical models with large amounts of business data.

Senior Data Scientist

Understanding problems and building models based on the data collected and leading a team of data scientists.

AI Expert

Developing strategies for frameworks and technologies to develop AI solutions and drive business success.

Machine Learning Expert

Using various machine learning tools and technologies, building statistical models with large amounts of business data.

Target Audience

Experienced professionals, team leaders, and individuals looking to take a leading role in process improvement projects, as well as those aiming for advanced expertise in Lean Six Sigma, will benefit from the CLSSBB certification.

The CLSSBB certification is suitable for you if you:

- Have a deep understanding of Lean Six Sigma methodologies and advanced process improvement tools

- Are involved in leading or driving process improvement projects, or managing teams that use Lean Six Sigma techniques

- Require knowledge for the CLSSBB Certification Exam

- Want an internationally recognized certification to demonstrate your expertise in leading and executing complex process improvement initiatives.

Curriculum

The Certified Lean Six Sigma Black Belt (CLSSBB) certification is based on a comprehensive body of knowledge and best practices in Lean Six Sigma. The CLSSBB curriculum provides advanced skills for process improvement, leadership in large-scale projects, and strategic decision-making. Black Belt professionals are expected to lead and mentor Green Belts and teams, manage complex projects, and drive organization-wide process improvements.

Here’s an overview of the key elements of the CLSSBB curriculum:

- Live Course

- Self Paced

- Industry Expert

- Academic Faculty

The Certified Lean Six Sigma Black Belt (CLSSBB) exam focuses on the five key phases that are essential in Lean Six Sigma methodology. Black Belts lead high-level, complex projects and drive organizational change through deep expertise in process improvement:

Define

- In this phase, the problem is clearly defined, project goals are established, and key stakeholders are identified.

- Black Belts ensure alignment with organizational goals and define the project’s scope to maximize impact.

- Key processes: Define the Problem, Identify Stakeholders, Set Project Goals, Develop Project Charter, Define Success Criteria.

Measure

- This phase emphasizes advanced data collection techniques and defining key performance metrics (KPIs) to establish baselines and measure process performance.

- Black Belts lead data-driven efforts to accurately capture and quantify the current state of processes.

- Key processes: Identify Key Metrics, Collect Data, Create Process Maps, Measure Process Performance, Establish Baseline Data, Conduct Measurement System Analysis.

Analyze

- In the Analyze phase, Black Belts apply advanced statistical analysis and data interpretation techniques to identify the root causes of inefficiencies and defects.

- The goal is to uncover trends, patterns, and variations, leading to data-driven decision-making.

- Key processes: Perform Data Analysis, Identify Root Causes, Conduct Gap Analysis, Perform Regression Analysis, Use Hypothesis Testing, Identify and Analyze Variability.

Improve

- Black Belts develop and implement solutions that address root causes, optimize processes, and drive measurable improvements.

- This phase includes designing and testing solutions, refining improvements, and scaling up successful interventions across the organization.

- Key processes: Develop Improvement Plans, Implement Solutions, Test and Validate Improvements, Optimize Process Performance, Perform Design of Experiments (DOE), Implement Full-Scale Solutions.

Control

- In the Control phase, Black Belts ensure that process improvements are sustained and integrated into standard operations.

- Control mechanisms and monitoring systems are put in place to track long-term performance and prevent regression.

- Key processes: Monitor Process Performance, Implement Control Plans, Conduct Post-Implementation Reviews, Standardize Solutions, Ensure Long-Term Sustainability, Develop Control Charts.

The Certified Lean Six Sigma Black Belt (CLSSBB) exam focuses on ten critical knowledge areas that are essential for leading complex, cross-functional process improvement projects. Black Belts are responsible for advanced data analysis, team leadership, and aligning process improvements with organizational strategy:

1. Define

- Understanding the problem, establishing clear project goals, and identifying key stakeholders to align the project with organizational objectives.

- Key Processes:

- Develop Project Charter

- Define Project Scope

- Identify Stakeholders

- Align Project Goals with Business Objectives

- Key Processes:

2. Measure

- Collecting and analyzing data to establish baselines and define key performance indicators (KPIs) for ongoing process evaluation.

- Key Processes:

- Develop Data Collection Plan

- Define Performance Metrics

- Collect Data

- Create Process Maps

- Perform Measurement System Analysis (MSA)

- Key Processes:

3. Analyze

- Applying advanced analytical tools and techniques to identify the root causes of inefficiencies or defects in the process.

- Key Processes:

- Perform Data Analysis

- Conduct Root Cause Analysis

- Perform Gap Analysis

- Use Statistical Tools (Regression, Hypothesis Testing, etc.)

- Identify and Analyze Process Variability

- Key Processes:

4. Improve

- Developing and implementing solutions to address root causes, optimize process performance, and drive business results.

- Key Processes:

- Develop Improvement Plans

- Implement Solutions

- Test and Validate Improvements

- Optimize Process Performance

- Conduct Design of Experiments (DOE)

- Implement Full-Scale Solutions

- Key Processes:

5. Control

- Implementing control mechanisms to sustain improvements and monitor process performance over time.

- Key Processes:

- Monitor Process Performance

- Implement Control Plans

- Conduct Post-Implementation Reviews

- Standardize Solutions

- Ensure Long-Term Sustainability

- Key Processes:

6. Voice of the Customer (VOC)

- Understanding customer needs and ensuring that process improvements meet or exceed customer expectations.

- Key Processes:

- Gather and Analyze Customer Feedback

- Translate Customer Requirements into Technical Specifications

- Prioritize Customer Needs

- Key Processes:

7. Process Mapping

- Creating detailed process flow diagrams to identify inefficiencies and areas for improvement.

- Key Processes:

- Develop Process Flow Diagrams

- Conduct Value Stream Mapping

- Identify Value-Added and Non-Value-Added Activities

- Optimize Process Flows

- Key Processes:

8. Root Cause Analysis

- Identifying and addressing the root causes of inefficiencies, defects, and variations in processes.

- Key Processes:

- Conduct Fishbone Diagram (Ishikawa) Analysis

- Use Pareto Analysis

- Identify Systemic Issues

- Key Processes:

9. Statistical Analysis

- Using advanced statistical tools to analyze data, make informed decisions, and validate improvement outcomes.

- Key Processes:

- Apply Descriptive Statistics

- Perform Hypothesis Testing

- Use Statistical Process Control (SPC)

- Conduct Multivariate Analysis

- Key Processes:

10. Sustainability and Standardization

- Ensuring that improvements are standardized, maintained, and continue to deliver value over time.

- Key Processes:

- Develop Standard Operating Procedures (SOPs)

- Ensure Ongoing Monitoring and Control

- Establish Process Ownership and Accountability

- Develop Process Documentation

- Key Processes:

The CLSSBB exam focuses on four key domains of Lean Six Sigma principles, reflecting an advanced level of expertise in process improvement and quality management. These domains emphasize leadership, advanced data analysis, and strategic business impact, ensuring that professionals can effectively lead and manage large-scale projects. The domains include:

People (40%)

- Focuses on advanced leadership, team management, coaching, and mentoring.

- Emphasizes the Black Belt’s role in managing cross-functional teams, developing high-performing teams, and driving organizational change through process improvement.

Process (45%)

- Covers advanced tools and techniques, including multivariate analysis, design of experiments (DOE), regression analysis, and statistical process control (SPC).

- Focuses on advanced application of the DMAIC methodology to solve complex process issues, drive large-scale improvements, and ensure sustainable results.

Business Context (10%)

- Highlights the alignment of process improvement projects with strategic business objectives and organizational goals.

- Focuses on creating value through process optimization, improving customer satisfaction, and aligning Lean Six Sigma initiatives with long-term business success.

Advanced Analytical Tools (5%)

- Delves into advanced statistical methods and analytical tools necessary for identifying, analyzing, and solving high-level process problems.

- Emphasizes tools such as multivariate analysis, simulation models, and optimization techniques to guide decision-making and process redesign.

The Certified Lean Six Sigma Black Belt (CLSSBB) curriculum provides an in-depth understanding of advanced Lean Six Sigma concepts and tools, preparing professionals to lead complex improvement projects and mentor teams. The curriculum focuses on strategic problem-solving, advanced statistical analysis, and leadership in organizational change. Key areas include:

Advanced Lean Principles

- Focuses on identifying and eliminating waste at the enterprise level and optimizing the entire value stream.

- Emphasizes tools such as Value Stream Mapping (VSM), Kaizen, and pull systems for improving overall efficiency and reducing costs across multiple processes.

Advanced Six Sigma Techniques

- Deepens the understanding of the DMAIC methodology, with a focus on advanced problem-solving techniques, including hypothesis testing, regression, and multivariate analysis.

- Introduces Design for Six Sigma (DFSS) and Lean Six Sigma integration for optimizing product and process designs.

Leadership and Mentorship

- Focuses on the Black Belt’s role as a leader and mentor, guiding and supporting Green Belts and Yellow Belts through their process improvement projects.

- Emphasizes advanced problem-solving skills, conflict management, and leading organizational change to foster a culture of continuous improvement.

Data-Driven Decision Making

- Equips Black Belts with advanced knowledge of data collection, statistical analysis, and data interpretation to drive decision-making.

- Emphasizes the use of advanced tools like statistical process control (SPC), regression analysis, and multivariate analysis to identify trends and opportunities for improvement.

Business Strategy and Impact

- Focuses on the alignment of Lean Six Sigma initiatives with strategic business goals, ensuring that improvements deliver measurable results and drive business value.

- Stresses the importance of managing large-scale projects, delivering sustainable improvements, and ensuring long-term success.

To maintain your Certified Lean Six Sigma Black Belt (CLSSBB) certification, you must earn 50 PDUs every 3 years by participating in ongoing education and professional development activities. These activities include:

- Attending advanced Lean Six Sigma training, workshops, and conferences.

- Participating in webinars and seminars focused on advanced statistical techniques, process optimization, and leadership.

- Engaging in learning opportunities that enhance expertise in process management, statistical analysis, and organizational leadership.

Program Highlights

- 55% Average Salary Hike

- 55% Average Salary Hike

- 12000+ Career Transitions

- 400+ Hiring Partners

Conclusion

Black Belts represent the highest level of proficiency in Lean Six Sigma. They lead large, complex projects, utilizing advanced analytical techniques and leadership skills to drive strategic change across the organization. Black Belts mentor and guide Green and Yellow Belts, ensuring the successful execution of process improvement strategies while fostering a culture of continuous improvement. Their role extends beyond project execution, influencing organizational strategy, maximizing business value, and ensuring long-term sustainability of improvements.

Dos and Don'ts

Preparing for the Certified Lean Six Sigma Black Belt (CLSSBB) exam requires careful planning, a thorough understanding of the exam content, and effective study techniques. Below are key dos and don’ts to guide your preparation and approach to the exam:

Do Master the DMAIC Methodology

The DMAIC (Define, Measure, Analyze, Improve, Control) framework is the foundation of Lean Six Sigma. Ensure you fully understand each phase and how to apply it to complex projects.- Focus on each step with attention to detail and practical application.

Do Develop Strong Statistical Skills

As a Black Belt, you’ll need advanced statistical knowledge. Make sure to:- Learn key statistical tools like hypothesis testing, regression analysis, ANOVA, and control charts.

- Practice applying them to real-world problems.

Do Practice Process Improvement Case Studies

Case studies provide a great way to apply theoretical knowledge to practical scenarios.- Work through different case studies that involve analyzing data, identifying issues, and applying solutions using Lean Six Sigma principles.

Do Study Lean Principles Thoroughly

Lean concepts such as waste reduction, continuous improvement, and value stream mapping are essential.- Ensure you understand Lean tools like Value Stream Mapping (VSM), Kaizen, and 5S.

Do Understand Leadership and Team Management

As a Black Belt, you’ll lead teams and drive projects. Focus on:- Developing leadership skills to manage team dynamics.

- Learning how to engage stakeholders and drive change.

Do Focus on Advanced Problem-Solving Techniques

Black Belt-level problems require advanced techniques. Study:- Root cause analysis, failure mode effects analysis (FMEA), and design of experiments (DOE).

- These techniques are vital for solving complex problems in process improvement.

Do Take Mock Exams

Practice with mock exams to get familiar with the exam format and timing.- Use these practice tests to identify weak areas and reinforce your knowledge.

Do Review the Exam Content Outline

The exam content outline will guide your study efforts.- Use it to focus on the key domains and topics that are emphasized on the exam.

Do Leverage Study Groups and Forums

Engage with other candidates or professionals in study groups or forums.- This will give you access to new perspectives, problem-solving techniques, and tips for exam preparation.

Do Maintain a Balanced Study Routine

Prepare a realistic study plan that balances learning with rest.

- Set aside time for breaks, exercise, and relaxation to keep your mind sharp and reduce stress.

Don’t Ignore Basic Concepts

Skipping foundational concepts can lead to gaps in your understanding, which may impact your performance on the exam.- Ensure you have a strong grasp of Lean Six Sigma principles before diving into advanced topics.

Don’t Cram at the Last Minute

The CLSSBB exam covers a broad range of topics that require deep understanding.- Avoid cramming; instead, spread your study over a period of weeks or months for better retention.

Don’t Rely Solely on Theory

While theory is important, real-world application is key.- Don’t just read; make sure you apply Lean Six Sigma tools to practical scenarios and case studies.

Don’t Overlook Statistical Software

As a Black Belt, you’ll need to work with statistical tools and software.- Avoid neglecting practice with software like Minitab or Excel, as these tools are essential for data analysis.

Don’t Skip Practice Exams

Practice exams help familiarize you with the exam format and question types.- Avoid taking the exam without first testing yourself with mock exams to identify weak areas.

Don’t Assume You’ll Remember Everything

The exam will test detailed knowledge across various topics.- Don’t rely on memory alone; take notes, create summaries, and review them regularly.

Don’t Disregard Time Management

The exam has a time limit, so pacing yourself is crucial.- Don’t waste time on difficult questions; move on and return to them if needed.

Don’t Skip Exam Content Review

The exam content outline provides a roadmap of what will be tested.- Don’t ignore it; use it to focus your study on the most important areas.

Don’t Neglect Your Health

Mental clarity is vital for exam success.- Avoid overstudying to the point of burnout; get enough sleep, exercise, and maintain a balanced diet.

Don’t Rely on One Resource

Lean Six Sigma is a vast field, and one resource may not cover everything.

- Don’t stick to only one textbook or course; supplement your studies with additional materials and practice problems.

Additional Tips for CLSSBB Exam Success:

Get Familiar with the Exam Interface: If available, take a practice test to familiarize yourself with the exam platform and navigation, ensuring you’re comfortable with the layout and question format.

Stay Updated on Exam Changes: Keep an eye on any updates to the CLSSBB exam content or format. CertiPLUS may periodically update the exam, so reviewing the latest guidelines is crucial before your test.

Take the CLSSBB Exam Seriously: The exam is challenging, but with focused preparation and the right mindset, success is achievable. Stay disciplined, maintain a positive attitude, and trust in your preparation.

- Practice 20+ Essential Tools

- Designed by Industry Experts

- Get Real-world Experience

- Beginner

- Intermediate

- Advance

In this classic classification problem, we will use a supervised learning approach involving classification algorithms and optimize the predictions by minimizing the error in predictions.

Reviews

Reviews on the Certified Project Management Practitioner Plus (CPMP+), Powered by CertiPLUS certification is very positive, particularly for those seeking to formalize their project management skills and advance their careers. Here are some key points typically highlighted in reviews of the CPMP+:

Positive: The CLSSBB certification is globally recognized and highly valued, opening doors to senior roles, such as project manager or process improvement leader. It enhances career prospects and offers potential salary increases.

Negative: Recognition may vary by industry or region, and in some cases, practical experience or other qualifications may be preferred over certification alone.

Positive: The CLSSBB curriculum is comprehensive, providing advanced tools and techniques for leading large-scale projects and mentoring others, driving organizational change.

Negative: The material is complex, requiring significant time and effort to understand, especially for those new to advanced data analysis or leadership.

Positive: Preparation for CLSSBB is well-supported with extensive resources, including courses and study guides that cover the necessary tools for the exam.

Negative: The preparation process can be time-consuming and challenging, particularly for those balancing work and study.

Positive: The CLSSBB exam is challenging but achievable with proper preparation, testing advanced knowledge in process improvement, data analysis, and leadership.

Negative: The exam is difficult, particularly sections on statistical analysis and leadership, requiring thorough preparation.

Positive: CLSSBB is globally recognized, enhancing career opportunities in industries such as manufacturing, healthcare, and technology.

Negative: The value of the certification may vary in some regions or industries where Lean Six Sigma is less emphasized.

Positive: CLSSBB is a strong investment, offering high returns in terms of career advancement, leadership opportunities, and salary growth.

Negative: The certification requires significant time and financial investment, which can be challenging for busy professionals.

Positive: Post-certification, CLSSBB professionals often experience career growth, leadership roles, and higher salaries due to their expertise in process improvement.

Negative: The post-certification value may depend on continued skill development and industry-specific demand for Lean Six Sigma expertise.

Overall Review Summary:

The CLSSBB certification is highly respected and opens doors to senior roles, offering career growth, leadership opportunities, and higher salaries. It equips professionals with advanced process improvement and data analysis skills.

While challenging, the certification offers a strong return on investment for those committed to continuous improvement and leadership in Lean Six Sigma.

Our Alumni Works At

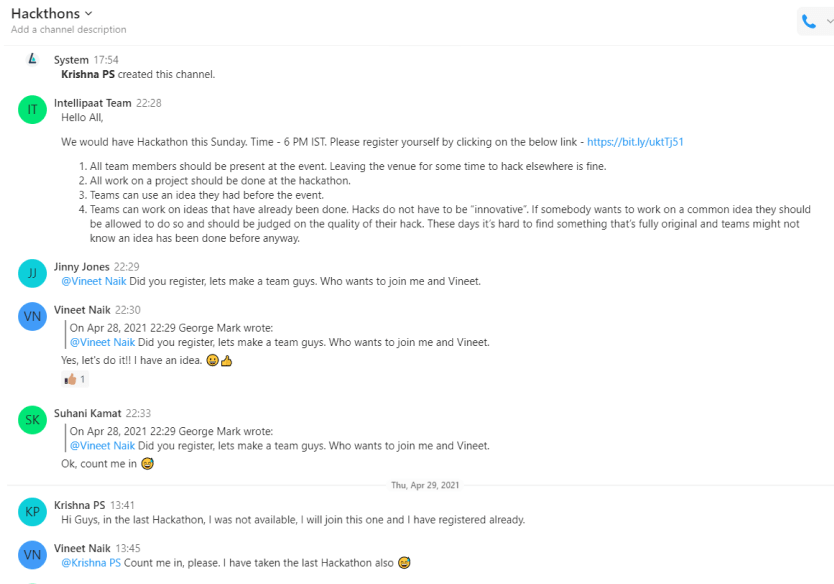

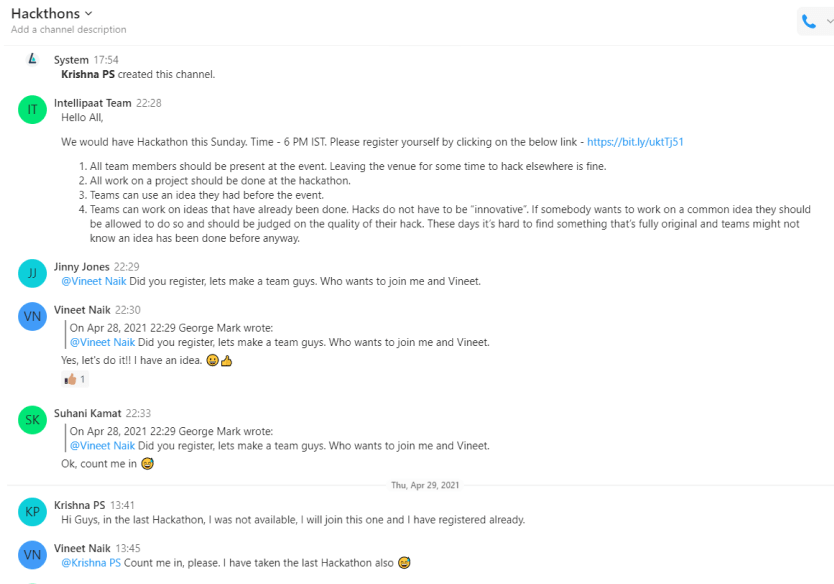

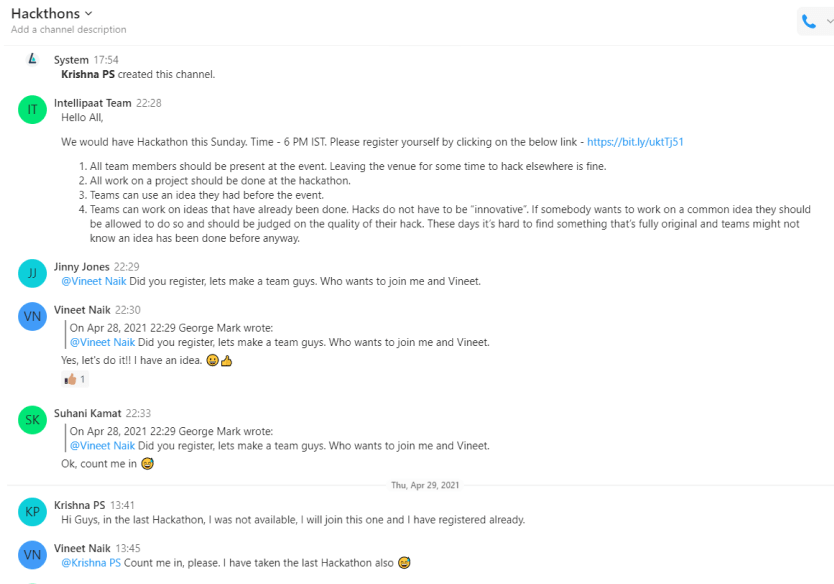

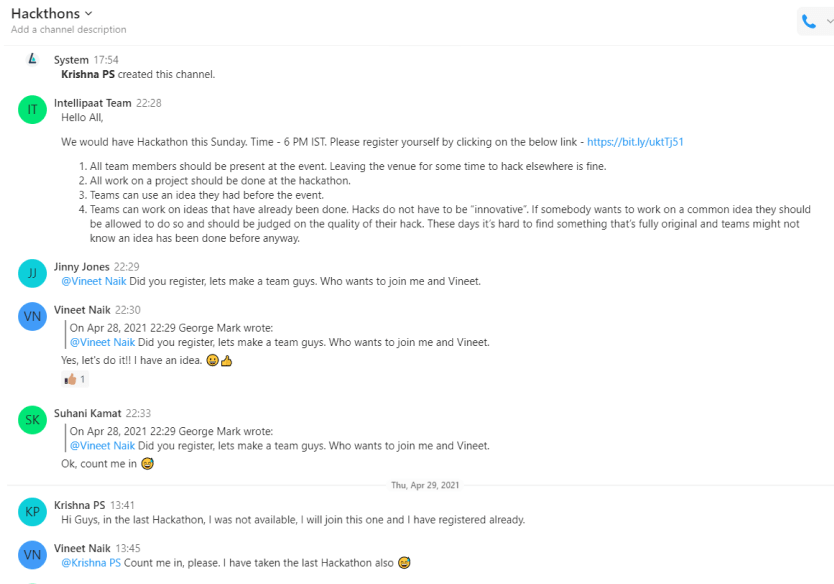

Peer Learning

Via Certiplus, you can interact with your peers across all classes and batches and even our alumni. Collaborate on projects, share job referrals & interview experiences, compete with the best, make new friends – the possibilities are endless and our community has something for everyone!

- Class Notifications

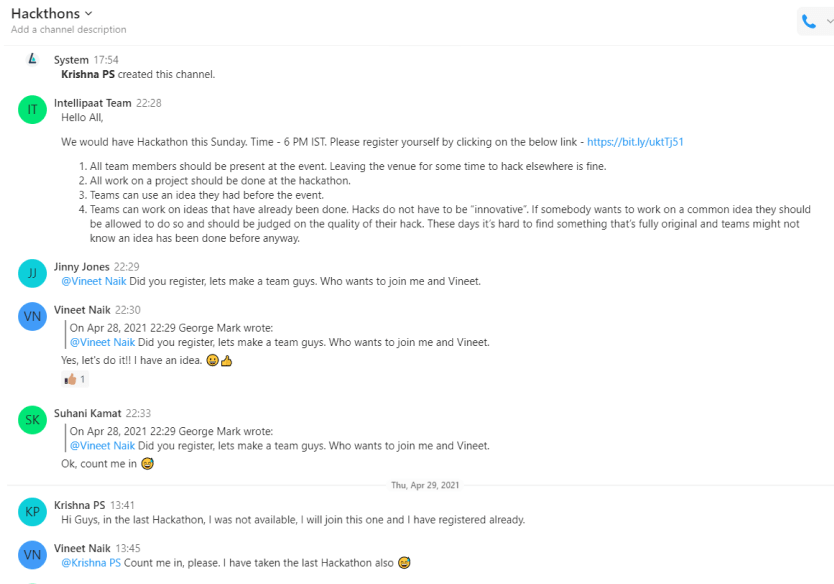

- Hackathons

- Career Services

- Major Announcements

- Collaborative Learning