Certified | Project Management Practitioner PLUS

Powered by CertiPLUS

Certified Lean Six Sigma Green Belt (CLSSGB) certification enhances process improvement skills, empowering professionals to lead projects and drive efficiency using Lean Six Sigma methods.

The Certified Lean Six Sigma Green Belt (CLSSGB) certification provides essential knowledge for excelling in quality management and process improvement roles. It’s an excellent stepping stone for those aiming for mid-level positions in process optimization.

As more organizations adopt Lean Six Sigma methodologies, this certification offers a strong foundation for advancing your career in process improvement and operational excellence.

- Your first stepping stone to a career in the field

Exam Pattern

Multiple Choice Questions

Mode of Exam

Online from Home or Office

Duration of Exam

3 Hours

Open Book/Closed Book

Closed Book Exam

Certification Validity

3 Years

About Program

The Certified Lean Six Sigma Green Belt (CLSSGB) program trains professionals to lead process improvement projects using Lean Six Sigma methods. It focuses on data analysis, process optimization, and problem-solving techniques.

Graduates are equipped to drive efficiency, support larger projects, and contribute to continuous improvement efforts within their organizations.

1. Overview of CLSSGB

The Certified Lean Six Sigma Green Belt (CLSSGB) certification is designed for professionals who want to develop expertise in process improvement methodologies. It validates your ability to analyze and solve quality-related issues, lead teams, and implement Lean Six Sigma principles within organizations. Green Belts often manage smaller projects or work as team members on larger projects led by Black Belts. This certification is widely recognized across industries such as manufacturing, healthcare, IT, and finance.

2. CLSSGB Certification Requirements

- Educational Requirements:

- With a Four-Year Degree (Bachelor’s or Equivalent): 3 years of professional experience in process improvement or related fields.

- With a High School Diploma or Associate’s Degree: 5 years of professional experience in process improvement or related fields.

- Project Management Experience: Hands-on experience in leading or participating in process improvement projects. The experience must involve applying Lean Six Sigma methodologies to solve real-world problems.

- Training Hours: A minimum of 35 hours of formal Lean Six Sigma Green Belt training. Training can be completed through accredited programs, online courses, or workshops.

3. CLSSGB Exam Overview

The CLSSGB exam assesses candidates on their knowledge of Lean Six Sigma methodologies and tools. As of the latest update, the exam consists of:

- 100 multiple-choice questions

- Time limit: 180 minutes

- The exam covers the key concepts, tools, and techniques of Lean Six Sigma, including the DMAIC framework (Define, Measure, Analyze, Improve, Control), data analysis, and problem-solving methods.

4. Key Areas Tested in the CLSSGB Exam

The CLSSGB exam tests candidates’ understanding in several key areas, which include:

- Define Phase: Identifying project goals, defining the problem, and determining the scope of the project.

- Measure Phase: Collecting and analyzing data to establish baselines and measure project performance.

- Analyze Phase: Identifying root causes of problems and using data analysis tools to assess the process.

- Improve Phase: Designing and implementing solutions to improve the process and solve the identified issues.

- Control Phase: Ensuring the improvements are sustained over time and developing systems for monitoring the process.

5. Lean Six Sigma Tools Covered

In the CLSSGB certification, candidates are tested on their knowledge and application of a variety of Lean Six Sigma tools, such as:

- Pareto Charts for identifying key problems.

- Fishbone Diagrams (Ishikawa) for root cause analysis.

- Control Charts for monitoring process stability.

- Process Mapping for understanding workflows and identifying inefficiencies.

- FMEA (Failure Mode and Effects Analysis) to assess risk in processes.

6. CLSSGB Exam Process

- Step 1: Meet Eligibility Requirements: Ensure you meet the required education and experience criteria.

- Step 2: Apply for the CLSSGB Exam: Submit your application online through a Lean Six Sigma certifying body’s website. After your application is approved, you’ll be eligible to schedule the exam.

- Step 3: Pay the Exam Fee: Once your application is accepted, pay the exam fee. The typical cost is between $300 and $500 depending on the certifying body.

- Step 4: Schedule the Exam: After payment, schedule your exam with an authorized exam provider like Pearson VUE. Exams can be taken at testing centers or online with remote proctoring.

- Step 5: Prepare for the Exam: Study the Lean Six Sigma Green Belt material using training materials, practice exams, and sample questions to ensure thorough preparation.

- Step 6: Take the Exam: The CLSSGB exam is computer-based, and you’ll have 3 hours to complete the 100 questions. You’ll receive your results immediately after finishing the exam.

7. CLSSGB Exam Costs

- Exam Fees: The cost for the CLSSGB exam can range from $300 to $500, depending on the certifying body.

- Study Materials: Additional costs may include study guides, courses, or practice exams, which may range from $100 to $400.

8. Benefits of CLSSGB Certification

- Career Advancement: CLSSGB certification enhances your credibility as a process improvement expert, opening up opportunities for career advancement in a variety of industries such as manufacturing, healthcare, finance, and IT.

- Increased Earning Potential: Green Belt holders often see higher salaries as they bring valuable skills to organizations looking to improve quality and efficiency.

- Skill Development: The certification equips you with essential problem-solving and data analysis skills that help you drive successful projects and contribute to organizational growth.

- Improved Organizational Impact: As a Green Belt, you can lead process improvement projects, reduce waste, and enhance customer satisfaction, contributing directly to the success of your organization.

9. CLSSGB vs Other Certifications

- Green Belt vs Yellow Belt: The Green Belt is a more advanced certification compared to Yellow Belt. While Yellow Belt holders support projects as team members, Green Belt holders lead projects, manage teams, and make decisions to drive improvement.

- Green Belt vs Black Belt: Green Belts typically lead smaller projects or work under Black Belts in larger, complex projects. Black Belts are responsible for managing the most complex projects and overseeing Green Belts.

- Green Belt vs PMP (Project Management Professional): While the PMP focuses on general project management skills across industries, the Green Belt certification focuses specifically on process improvement using Lean Six Sigma methodologies.

10. Continuing Certification Requirements (CCR)

- Recertification: Lean Six Sigma Green Belt certification typically does not require recertification, but candidates are encouraged to stay engaged in process improvement activities to maintain their expertise.

- Professional Development: Continuing education is recommended, and many professionals pursue higher certifications like Lean Six Sigma Black Belt or project management certifications (e.g., PMP) to further enhance their career prospects.

11. Exam Preparation Tips for CLSSGB

- Review the DMAIC Framework: The DMAIC (Define, Measure, Analyze, Improve, Control) methodology is the backbone of Lean Six Sigma. Understand each phase in detail and how it applies to real-world projects.

- Practice with Sample Questions: Familiarize yourself with the exam format by practicing with sample questions. This will help you get comfortable with the exam structure and improve your time management.

- Study Lean Six Sigma Tools: Focus on learning the key tools like Pareto charts, fishbone diagrams, control charts, and FMEA, as these are frequently tested in the exam.

- Join Study Groups: Engage with other Lean Six Sigma Green Belt candidates through online forums or local study groups to share knowledge, resources, and tips for exam preparation.

Conclusion

The Certified Lean Six Sigma Green Belt (CLSSGB) certification is a great way for professionals to gain expertise in process improvement and contribute to organizational success. Whether you are new to Lean Six Sigma or looking to formalize your skills, this certification provides the tools and knowledge to help you lead projects effectively and make impactful improvements. With a thorough understanding of Lean Six Sigma methodologies, you’ll be well-positioned to advance your career and contribute meaningfully to your organization’s growth.

Key Highlights

- 620 Hrs of Applied Learning

- 218 Hrs of Self-Paced Learning

- 50+ Industry Projects & Case Studies

- 24*7 Support

- 1:1 Mock Interview

- iHUB DivyaSampark, IIT Roorkee Certification

- 2 Days Campus Immersion at IIT Roorkee

- Top 2 performers per batch will receive Rs 80000 in fellowship*

- Free Voucher for Exam AZ-900: Microsoft Azure Fundamentals worth $99

- 90+ Live Sessions Across 11 months

- Learn from IIT Faculty & Industry Practitioners

- One-on-One with Industry Mentors

- Dedicated Learning Management Team

- No-Cost EMI Option

- Designed for Working Professionals and Freshers

- Up to Rs. 50 Lakhs startup Incubation Support*

- 3 Guaranteed Job Interviews upon movement to Placement Pool

Career Transition

- 55% Average Salary Hike

- 55% Average Salary Hike

- 12000+ Career Transitions

- 400+ Hiring Partners

Who Can Apply for the Course?

- Individuals with a bachelor’s degree and a strong interest in learning AI and data science

- IT professionals looking to make a career transition as data scientists and artificial intelligence engineers

- Software Developer, Project managers, Non-Technical Professionals & Entry-level professionals looking to build their careers in artificial intelligence and data science

- Undergraduate freshers with an interest in Data Science & AI

What roles can a person trained in data science and artificial intelligence play?

Senior Data Scientist

Understanding problems and building models based on the data collected and leading a team of data scientists.

AI Expert

Developing strategies for frameworks and technologies to develop AI solutions and drive business success.

Machine Learning Expert

Using various machine learning tools and technologies, building statistical models with large amounts of business data.

Senior Data Scientist

Understanding problems and building models based on the data collected and leading a team of data scientists.

AI Expert

Developing strategies for frameworks and technologies to develop AI solutions and drive business success.

Machine Learning Expert

Using various machine learning tools and technologies, building statistical models with large amounts of business data.

Target Audience

Professionals, team members, and students at the graduate or undergraduate level, as well as individuals starting their careers or those seeking to enhance their process improvement skills, will benefit from the CLSSGB certification.

The CLSSGB certification is suitable for you if you:

- Have a solid understanding of Lean Six Sigma principles and basic process improvement techniques

- Are actively involved in process improvement projects or working in a team that uses Lean Six Sigma tools

- Require knowledge for the CLSSGB Certification Exam

- Want an internationally recognized certification that demonstrates your ability to contribute to process improvement initiatives.

Curriculum

The Certified Lean Six Sigma Green Belt (CLSSGB) certification is based on a comprehensive body of knowledge and best practices defined in the Lean Six Sigma methodology. The CLSSGB curriculum builds on foundational Lean Six Sigma principles, expanding into more advanced process improvement techniques, data analysis, and project leadership skills.

Here’s an overview of the key elements of the CLSSGB curriculum:

- Live Course

- Self Paced

- Industry Expert

- Academic Faculty

The Certified Lean Six Sigma Green Belt (CLSSGB) exam focuses on the five key phases of the Lean Six Sigma methodology, providing Green Belts with the necessary tools to lead and manage process improvement projects. These phases are integral to achieving sustainable process improvements and maximizing business outcomes:

Define

- In this phase, the project’s scope and objectives are clearly defined, with a focus on identifying key stakeholders and understanding the problem.

- The Define phase ensures that the improvement effort is properly scoped and aligned with organizational goals.

- Key processes: Define the Problem, Identify Stakeholders, Set Project Goals, Develop Project Charter, Define Success Criteria.

Measure

- This phase focuses on data collection and process performance measurement to understand the current state.

- Green Belts gather relevant data and establish baseline metrics to evaluate process effectiveness.

- Key processes: Identify Key Metrics, Collect Data, Create Process Maps, Measure Process Performance, Establish Baseline Data.

Analyze

- The Analyze phase utilizes data to identify the root causes of inefficiencies or problems.

- Green Belts apply advanced analytical techniques to uncover patterns, variations, and defects in the process.

- Key processes: Root Cause Analysis, Statistical Analysis, Process Analysis, Identify Variations and Defects, Conduct Hypothesis Testing.

Improve

- In the Improve phase, solutions are developed, tested, and implemented to address the root causes identified in the Analyze phase.

- Green Belts focus on optimizing processes by piloting solutions, evaluating effectiveness, and refining improvements.

- Key processes: Develop Solutions, Test and Pilot Solutions, Implement Improvements, Optimize Process, Design and Implement Solutions.

Control

- The Control phase focuses on sustaining improvements and ensuring the long-term success of the project.

- Green Belts establish monitoring systems and control plans to maintain performance and prevent regression.

- Key processes: Monitor Process, Establish Control Plans, Standardize Solutions, Implement Control Systems, Track Ongoing Performance.

The Certified Lean Six Sigma Green Belt (CLSSGB) exam focuses on the ten essential knowledge areas that are critical for effectively applying Lean Six Sigma methodologies and practices in process improvement projects:

1. Define

- Understanding the problem, establishing clear project goals, and identifying key stakeholders to ensure alignment with organizational objectives.

- Key Processes:

- Develop Project Charter

- Define Project Scope

- Identify Stakeholders

- Key Processes:

2. Measure

- Collecting and measuring data to establish baselines and identify key performance metrics for the process.

- Key Processes:

- Develop Data Collection Plan

- Define Performance Metrics

- Collect Data

- Create Process Maps

- Key Processes:

3. Analyze

- Analyzing collected data to uncover root causes of inefficiencies and identify areas for improvement.

- Key Processes:

- Perform Data Analysis

- Identify Root Causes

- Conduct Gap Analysis

- Perform Regression Analysis

- Key Processes:

4. Improve

- Developing and testing solutions to address the root causes of problems and optimize processes.

- Key Processes:

- Develop Improvement Plans

- Implement Solutions

- Test and Validate Improvements

- Optimize Process Performance

- Key Processes:

5. Control

- Ensuring that improvements are maintained over time by implementing control mechanisms and monitoring ongoing performance.

- Key Processes:

- Monitor Process Performance

- Implement Control Plans

- Conduct Post-Implementation Reviews

- Ensure Sustainable Results

- Key Processes:

6. Voice of the Customer (VOC)

- Understanding customer needs and ensuring that improvements meet or exceed customer expectations.

- Key Processes:

- Gather Customer Feedback

- Analyze Customer Requirements

- Prioritize Customer Needs

- Key Processes:

7. Process Mapping

- Creating visual representations of processes to better understand and identify areas for improvement.

- Key Processes:

- Develop Process Flow Diagrams

- Conduct Value Stream Mapping

- Identify Waste and Non-Value-Added Activities

- Key Processes:

8. Root Cause Analysis

- Identifying the root causes of inefficiencies or defects in the process to focus improvement efforts.

- Key Processes:

- Conduct Fishbone Diagram Analysis (Ishikawa)

- Use Pareto Analysis

- Identify Systemic Issues

- Key Processes:

9. Statistical Analysis

- Using statistical tools to analyze data, make informed decisions, and validate improvement outcomes.

- Key Processes:

- Apply Descriptive Statistics

- Perform Hypothesis Testing

- Use Statistical Process Control (SPC)

- Key Processes:

10. Sustainability and Standardization

- Ensuring that improvements are standardized and maintained over time, embedding continuous improvement into the organization.

- Key Processes:

- Develop Standard Operating Procedures (SOPs)

- Ensure Ongoing Monitoring and Control

- Establish Process Ownership and Accountability

- Key Processes:

The CLSSGB exam focuses on three key domains of Lean Six Sigma principles, designed to ensure a deeper understanding of process improvement practices and their application. These domains reflect a comprehensive approach to quality management and process optimization, with an emphasis on both strategic and technical aspects. The domains include:

People (42%)

- Focuses on leadership, team collaboration, effective communication, and conflict resolution.

- Emphasizes the role of Green Belts in leading cross-functional teams, managing stakeholder engagement, and driving continuous improvement initiatives.

Process (50%)

- Covers advanced Lean Six Sigma tools, such as statistical process control (SPC), process mapping, hypothesis testing, and regression analysis.

- Focuses on the application of the DMAIC (Define, Measure, Analyze, Improve, Control) methodology to optimize processes and achieve sustainable improvements.

Business Context (8%)

- Highlights the importance of aligning process improvement projects with organizational goals and strategic objectives.

- Emphasizes delivering measurable value through process optimization and aligning Lean Six Sigma efforts with business outcomes.

The Certified Lean Six Sigma Green Belt (CLSSGB) curriculum introduces advanced Lean Six Sigma concepts and tools necessary for leading and managing improvement projects. These concepts are designed to deepen the understanding of process improvement and equip professionals with the skills to drive impactful change. Key areas include:

Lean Principles

- Focuses on identifying and eliminating waste, increasing flow, and improving value streams.

- Emphasizes Lean tools such as Value Stream Mapping (VSM), 5S, and Kaizen to improve efficiency and reduce operational costs.

Six Sigma Fundamentals

- Covers the complete DMAIC methodology in-depth, with a focus on analyzing data, defining problems, and implementing sustainable improvements.

- Introduces more advanced statistical techniques, including regression analysis, hypothesis testing, and design of experiments (DOE).

Team Leadership and Roles

- Explores the Green Belt’s role in leading cross-functional teams and driving process improvement projects.

- Focuses on building effective team dynamics, managing stakeholder expectations, and facilitating problem-solving sessions.

Data Analysis and Statistical Tools

- Provides a comprehensive understanding of data collection, measurement systems analysis, and statistical process control (SPC).

- Equips Green Belts with the ability to analyze complex data sets and use statistical software tools to drive decision-making.

Business Impact

- Stresses the alignment of Lean Six Sigma projects with broader business strategies and goals.

- Focuses on creating tangible improvements that result in cost savings, efficiency gains, and higher customer satisfaction.

To maintain your Certified Lean Six Sigma Green Belt (CLSSGB) certification, you must earn 50 PDUs every 3 years by participating in ongoing education and professional development activities. These activities include:

- Attending advanced Lean Six Sigma training sessions and workshops.

- Participating in webinars, conferences, and seminars that enhance knowledge of Lean Six Sigma methodologies.

- Engaging in learning opportunities that build on core competencies related to process improvement, statistical analysis, and leadership.

Program Highlights

- 55% Average Salary Hike

- 55% Average Salary Hike

- 12000+ Career Transitions

- 400+ Hiring Partners

Conclusion

Green Belts possess an intermediate level of expertise and play a more prominent role in leading small-to-medium scale projects. They are responsible for managing and executing improvement initiatives, utilizing advanced statistical tools and methodologies like DMAIC (Define, Measure, Analyze, Improve, Control) to identify root causes and implement solutions. Green Belts bridge the gap between project teams and leadership, ensuring that improvements are sustained and aligned with organizational goals.

Dos and Don'ts

Preparing for the Certified Lean Six Sigma Green Belt (CLSSGB) exam requires careful planning, a solid understanding of the exam content, and effective study techniques. Below are key dos and don’ts to guide your preparation and approach to the exam:

Do Thoroughly Understand Lean Six Sigma Principles

Lean Six Sigma is built on core principles that guide process improvement. Make sure to:- Grasp the DMAIC (Define, Measure, Analyze, Improve, Control) methodology

- Understand how to apply tools and techniques effectively in each phase

Do Practice with Real-Life Case Studies

Apply Lean Six Sigma concepts to real-world examples. Doing so will help you:- Improve problem-solving skills

- Understand how to implement process improvements in different industries

Do Use a Variety of Study Materials

Use multiple resources to deepen your understanding of Lean Six Sigma. This may include:- Books, online courses, webinars, and articles

- Practice exams and review guides

Do Master Key Tools and Techniques

Focus on mastering key tools that will be used in the exam, such as:- Process mapping, cause-and-effect diagrams, control charts, and hypothesis testing

- Statistical tools like regression analysis and design of experiments (DOE)

Do Take Practice Exams

Practice exams simulate the actual testing environment and help you:- Gauge your readiness

- Identify weak areas and focus on improving them

Do Review the Exam Content Outline

Review the exam content outline provided by the certifying body. This will help you:- Align your study plan with the exam’s structure

- Identify critical topics and focus areas

Do Focus on Data Analysis and Statistical Concepts

As a Green Belt, you’ll be expected to analyze data and understand statistical concepts. Make sure to:- Understand basic statistics, including hypothesis testing, regression analysis, and normal distribution

- Be able to interpret results from control charts and process capability analysis

Do Plan Your Study Time Wisely

Set a structured study schedule and stick to it. This will help you:- Manage your time effectively

- Break down complex topics into manageable sections for better retention

Do Engage with Study Groups

Study groups provide an opportunity to discuss difficult concepts and share insights. You can:- Ask questions and clarify doubts

- Learn from other candidates’ experiences and tips

Do Take Care of Your Health

Mental clarity is important for exam success. Don’t neglect your health, and:

- Get enough rest and sleep leading up to the exam

- Eat healthy meals, stay hydrated, and exercise regularly to keep your mind sharp

Don’t Rely on Only One Study Resource

Avoid relying on a single textbook or online course. Instead, use a variety of study materials to ensure comprehensive understanding.- Books, online resources, and practice exams should all be part of your study plan.

Don’t Skip the DMAIC Phases

The DMAIC (Define, Measure, Analyze, Improve, Control) methodology is the backbone of Lean Six Sigma. Don’t neglect any phase; ensure you understand each step in detail.- Skipping any phase may result in gaps in knowledge and weak performance in the exam.

Don’t Ignore Data Analysis

Data analysis and statistical tools are a significant part of the Green Belt exam. Don’t neglect learning statistical methods, such as regression analysis, hypothesis testing, and control charts.- Missing these topics could lead to struggles with data interpretation questions.

Don’t Overwhelm Yourself with Last-Minute Cramming

Cramming right before the exam will not lead to effective learning. Avoid:- Trying to learn everything in the last few days.

- Rushing through topics without fully understanding them.

Don’t Underestimate the Importance of Practice Exams

Avoid skipping practice exams and mock tests. They are essential for:- Understanding the format of the exam.

- Gaining confidence and improving time management skills.

Don’t Skip Reviewing Exam Content Outline

Not reviewing the exam content outline can lead to a lack of focus during your preparation.- The outline helps you know what areas to prioritize.

Don’t Forget the Real-World Application of Tools

Don’t just memorize Lean Six Sigma tools and techniques—understand how to apply them in real-world situations.- Focus on practical application during case studies and practice exams.

Don’t Overlook the Importance of Process Mapping

Process mapping is a core tool in Lean Six Sigma, and you should be able to create and analyze maps effectively.- Don’t avoid practicing this skill, as it’s vital for both the exam and real-world process improvements.

Don’t Assume All Questions Are Straightforward

Exam questions may be tricky, often requiring you to apply critical thinking and problem-solving.- Read each question carefully and avoid rushing through them.

Don’t Neglect Your Well-Being

Don’t let stress or poor health affect your performance.

- Make sure to balance study with breaks, and avoid last-minute cramming or sleep deprivation.

Additional Tips for CLSSGB Exam Success:

Get Familiar with the Exam Interface: If possible, complete a practice test to get used to the exam interface. This helps you navigate the questions and manage time effectively during the actual exam.

Stay Updated on Exam Changes: Make sure to check for any updates on the CLSSGB exam content or structure from CertiPLUS before your exam date. Being aware of any recent changes will help you feel more confident.

Take the CLSSGB Exam Seriously: The exam requires thorough preparation and a positive mindset. Stay focused on your studies, remain disciplined, and approach the exam with confidence to increase your chances of success.

- Practice 20+ Essential Tools

- Designed by Industry Experts

- Get Real-world Experience

- Beginner

- Intermediate

- Advance

In this classic classification problem, we will use a supervised learning approach involving classification algorithms and optimize the predictions by minimizing the error in predictions.

Reviews

Reviews on the Certified Project Management Practitioner Plus (CPMP+), Powered by CertiPLUS certification is very positive, particularly for those seeking to formalize their project management skills and advance their careers. Here are some key points typically highlighted in reviews of the CPMP+:

Positive: Earning the Certified Lean Six Sigma Green Belt (CLSSGB) certification enhances career prospects by demonstrating advanced problem-solving and analytical skills. It opens opportunities for mid-level roles in process improvement, quality management, and operational efficiency.

Negative: The certification may not immediately result in a job change or significant salary increase, especially in industries where Lean Six Sigma is not a primary focus. Further specialization or a Black Belt certification may be needed for senior roles.

Positive: The Certified Lean Six Sigma Green Belt (CLSSGB) curriculum offers a comprehensive understanding of process improvement methodologies. It covers advanced tools and techniques, equipping candidates with the knowledge to lead projects, analyze data, and drive process optimization within their teams.

Negative: Some individuals find the curriculum challenging, particularly if they are new to process improvement methodologies. It may require additional time and effort for those without prior experience in statistical analysis or Lean Six Sigma concepts.

Positive: Preparing for the Certified Lean Six Sigma Green Belt (CLSSGB) certification is well-supported with numerous resources, including online courses, study guides, and practice exams. These materials cater to candidates with some background in process improvement, making it easier to understand more complex tools and methodologies used in Lean Six Sigma.

Negative: Some candidates may struggle to find time for consistent preparation, particularly if they have demanding work or personal schedules. Additionally, the curriculum may focus more on theoretical concepts than real-world case studies, leaving some feeling less prepared for practical application in dynamic business environments.

Positive: The Certified Lean Six Sigma Green Belt (CLSSGB) exam is considered moderately challenging but manageable for those who have a solid understanding of Lean Six Sigma principles. With adequate preparation, candidates can demonstrate their ability to apply process improvement tools, data analysis, and problem-solving techniques effectively.

Negative: Some candidates find the exam challenging, particularly the sections involving statistical analysis and data interpretation. Those without a strong background in these areas may need additional study and practice to perform well in the exam.

Positive: The Certified Lean Six Sigma Green Belt (CLSSGB) certification is globally recognized, making it a valuable credential for professionals seeking to enhance their careers in process improvement, quality management, and operational excellence. It opens up opportunities for roles across various industries worldwide.

Negative: While globally recognized, the CLSSGB certification may not carry the same level of recognition in all industries or regions. In some organizations, it may be less valued compared to higher-level certifications, such as the Black Belt, depending on the organization’s focus on Lean Six Sigma methodologies.

Positive: The Certified Lean Six Sigma Green Belt (CLSSGB) certification offers a relatively affordable and time-efficient option for professionals looking to enhance their process improvement skills. The preparation time typically ranges from a few weeks to a couple of months, depending on individual schedules, with costs often lower compared to advanced certifications.

Negative: While the certification is cost-effective, the investment of time can be significant for some candidates, especially those balancing work or personal commitments. Additionally, the costs may add up when considering study materials, exam fees, and any preparatory courses needed for successful completion.

Positive: The Certified Lean Six Sigma Green Belt (CLSSGB) certification adds significant value post-certification by enhancing career prospects and professional credibility. It demonstrates proficiency in process improvement, data analysis, and project management, opening doors to new job opportunities, promotions, and the potential for higher salaries within various industries.

Negative: While the certification can improve career prospects, some individuals may find the post-certification value limited if they do not continue to build on their skills or pursue higher-level certifications, such as the Black Belt. The impact may also vary depending on the industry or organization’s focus on Lean Six Sigma methodologies.

Overall Review Summary:

The CLSSGB certification is a valuable credential for professionals looking to enhance their process improvement skills. It opens opportunities for mid-level roles in process optimization and operational efficiency, providing a strong foundation in Lean Six Sigma tools and techniques.

While the certification is less challenging than Black Belt, it requires significant effort to grasp key concepts. Overall, CLSSGB offers a good return on investment, boosting career prospects and enhancing problem-solving capabilities in various industries.

Our Alumni Works At

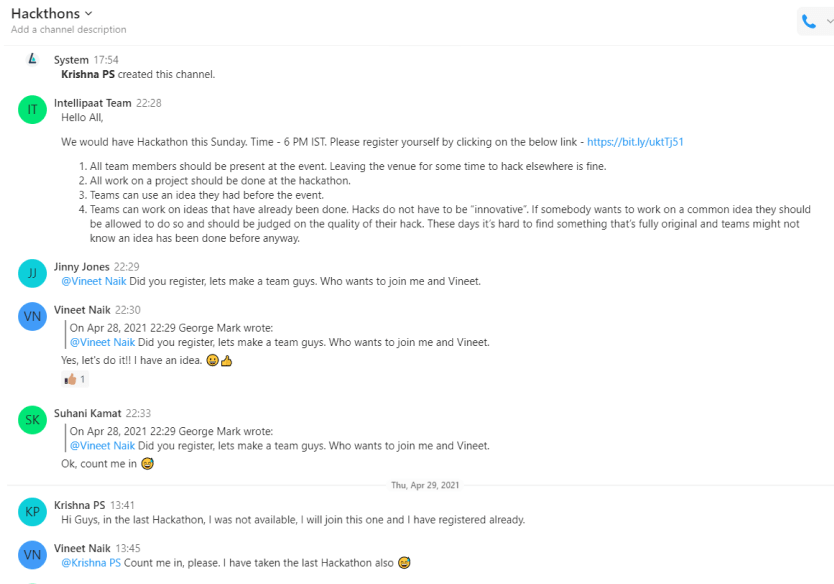

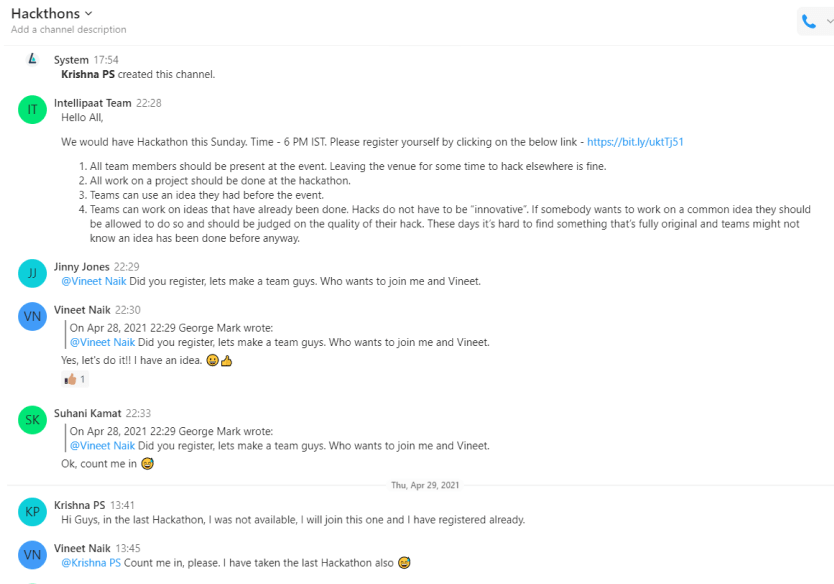

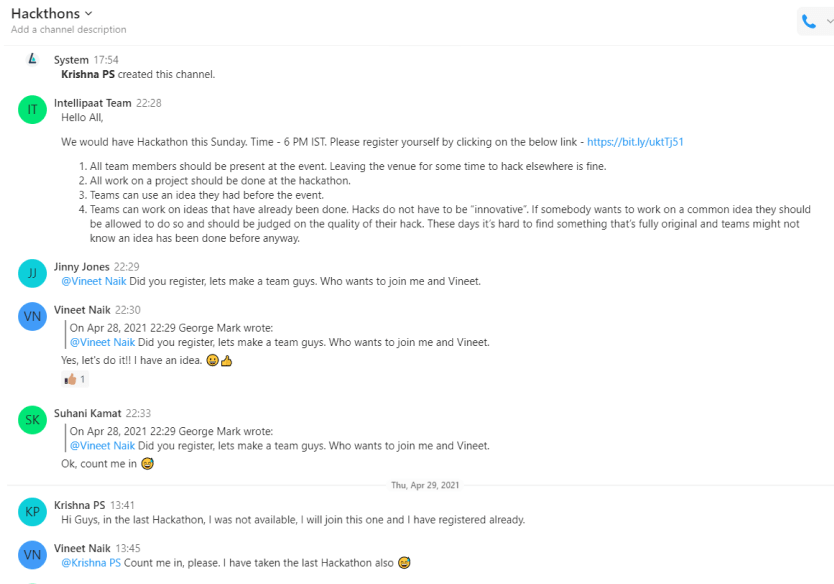

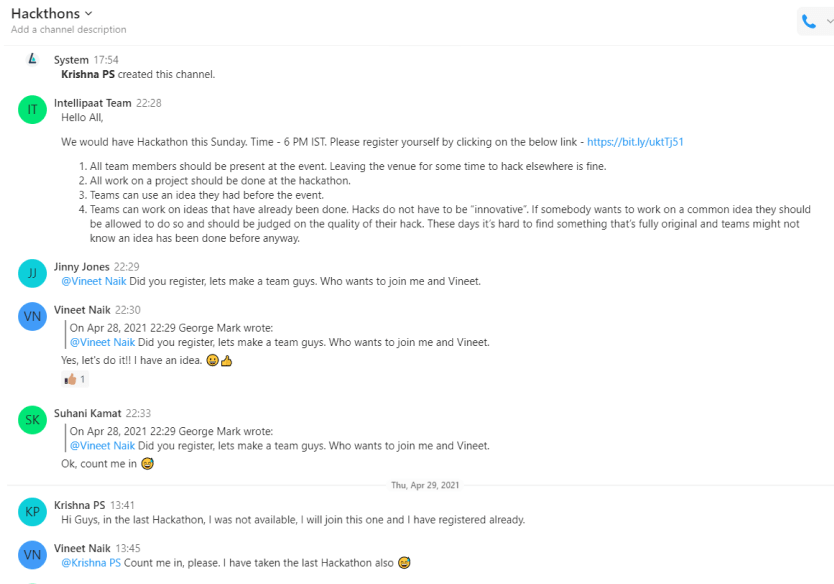

Peer Learning

Via Certiplus, you can interact with your peers across all classes and batches and even our alumni. Collaborate on projects, share job referrals & interview experiences, compete with the best, make new friends – the possibilities are endless and our community has something for everyone!

- Class Notifications

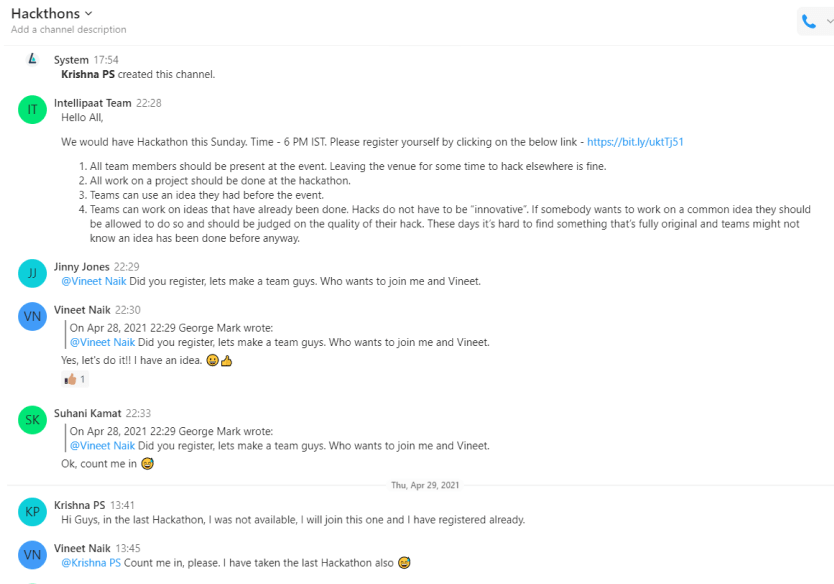

- Hackathons

- Career Services

- Major Announcements

- Collaborative Learning